Instructions

- Select or enter Calculation Input values in each of the red highlighted fields

- Select "Flange Class" and "Nominal Flange Diameter"

- If the finished flange face ID is known, enter it in the Finished Flange Seating Face ID box. Otherwise leave the box blank (ID assumed for the calculation is shown in the Calculation Data)

- Select "Gasket Style" and "Gasket Material"

- Input nut factor (based on lubricant friction factor)

- Once all red highlighted fields are filled out, select the CALCULATE button

- Review guidance found in the "Recommended Ranges"

Disclaimer

The authors, contributors, editors, and publisher do not assume responsibility for the validity of the content or any consequences of the use of this tool.

In no event will AWWA be liable for direct, indirect, special, incidental, or consequential damages arising out of the use of the information presented.

In particular, AWWA will not be responsible for any costs, including, but not limited to, those incurred as a result of lost revenue.

In no event shall AWWA’s liability exceed the amount paid for the purchase of AWWA Manual M11.

Input Information

Recommended Ranges

Target Torque

Bolt Stress At Torque

- Select a torque value within the recommended range and keep all bolts in the joint within 10% of that value

- Follow flange installation, bolt thread and face lubrication, and assembly guidance found in AWWA M11 and AWWA C604

- Follow the flange bolting pattern found in AWWA C604

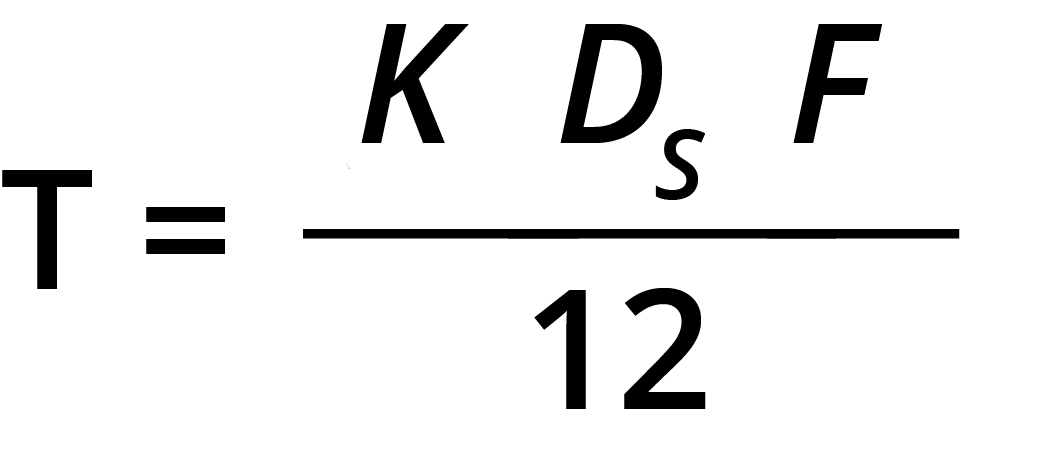

Calculations based on AWWA M11 Equation (12-2)

- T = Torque (ft-lbs)

- K = Nut Factor

- DS = Bolt Diameter (in)

- F = Bolt Load (lbs)

Calculation Data

AWWA C207 Flange Details

| Number of Bolts | - |

| Bolt Diameter, Ds (in) | - |

Bolt Yield Strength (psi)

|

- |

| Flange Face ID used for Calculation (in) | - |

| Flange OD (in) | - |

| Bolt Circle Diameter (in) | - |

| Gasket Seating Face Area (in2) | - |

| Bolt Cross Section Area (in2) | - |

Gasket Material Details

| Seating Stress (psi) | - |

| Crushing Stress (psi) | - |

Thread Lubricant

| Nut Factor for Calculation, K | - |

Bolt Yield Stress

| Bolt Stress at Gasket Seating (psi) | - |

| % of Bolt Yield at Gasket Seating | - |

| Bolt Stress at Gasket Crushing (psi) | - |

| % of Bolt Yield at Gasket Crushing | - |

| Torque at Gasket Seating (ft-lbs) | - |

| Torque at Gasket Crushing (ft-lbs) | - |

Disclaimer

The authors, contributors, editors, and publisher do not assume responsibility for the validity of the content or any consequences of the use of this tool.

In no event will AWWA be liable for direct, indirect, special, incidental, or consequential damages arising out of the use of the information presented.

In particular, AWWA will not be responsible for any costs, including, but not limited to, those incurred as a result of lost revenue.

In no event shall AWWA’s liability exceed the amount paid for the purchase of AWWA Manual M11.